What are CNC Machines?

CNC machines — also known as computer numerical control machines — are automated equipment that execute pre-programmed sequences of controlled commands to create a desired part. There are multiple different types of CNC machines; the type you’ll use to create your part will depend on the design.

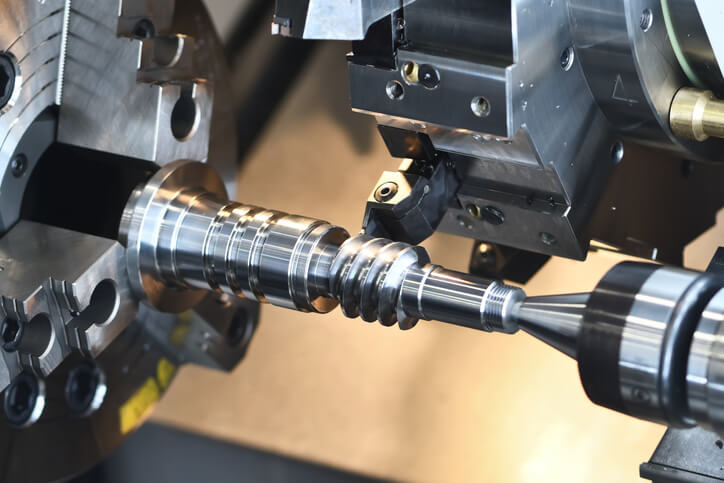

CNC Lathes and Turning Machines

CNC lathes and turning machines rotate (turn) materials during the machining operation. The cutting tool moves along the bar stock, removing material as it goes. These machines are best for making drilled holes, bores, brooches, tapers, threads, and more. As such, they’re commonly used to create screws, bolts, shafts, and poppets.

It’s important to note that there is a popular subset of the CNC lathes and turning machines category: CNC Swiss turning machines. Swiss turning machines can perform milling, drilling, knurling, turning, and boring processes. However, a traditional lathe and turning machine typically rotates rapidly in a fixed position, and is held firmly at one or both ends. A Swiss lathe allows the workpiece to turn and move back and forth along the Z-axis while tools create the features of the part.

CNC Milling Machines

CNC milling machines differ from lathes and turning machines because the cutting tool rotates while the workpiece is stationary. These machines are great for creating face-milled features (shallow, flat surfaces and cavities) and peripheral milled features (deep cavities like slots and threads). CNC milling machines most often produce square or rectangular shapes.

CNC Laser Machines

A CNC laser machine uses a laser to heat material, causing it to melt or vaporize. The machine features a laser head and lens assembly that focuses a laser beam (a column of high intensity light) onto the workpiece, which melts and cuts the workpiece into the desired shape. CNC lasers will also use a compressed gas to cool the focusing lens and expel the vaporized metal. These machines are best for cutting, slicing, or engraving metal materials.

CNC Waterjet Cutting Machines

Using a high pressure water jet, these machines can easily cut through metal and other types of material. It may use water alone to cut soft materials like wood and rubber. The water may also be mixed with an abrasive substance like garnet or aluminum oxide to cut harder materials.

Reach Out to Cameron Manufacturing & Design for Your CNC Machining Needs

When you need quality custom machining, trust Cameron Manufacturing & Design. We have a wide variety of CNC machining equipment to match your exact specifications. In addition to our state-of-the-art machinery, we also employ high-tech Creaform quality control equipment to scan our machined parts and verify quality. This equipment includes the MetraSCAN 750 Elite, HandyPROBE Next Elite, and MaxSHOT3D. These scans then feed directly into our VXinspect and VXmodel software to quickly and accurately measure all scanned parts and pair seamlessly with our CAD software.

With these time-test processes in place, we can perform geometric and freeform inspections on all of our custom machined, fabricated, and welded parts. Whether your project is less than 12 inches or more than 30 feet, we’ll ensure your products meet your exact expectations, every time.

We don’t just perform custom machining services, either. We also offer metal finishing, welding and fabrication, engineering design, and equipment installation services. We’re a one-stop-shop for all your manufacturing needs.

Start Working with Cameron Manufacturing & Design Today

No matter your need, we’ve got you covered. Reach out to us today for an initial consultation.

Recent Posts

- Crafting Excellence Bridging Heavy Fabrication and Light Manufacturing

- What is Precision Sheet Metal Fabrication

- Unveiling the Power of Custom Manufacturing Equipment in NY

- Cameron Manufacturing & Design: Your Top Choice for CNC Laser Projects

- The Power of Precision Machining in Custom Metal Fabrication

Trust the CMD Team With Your Next Project

Our highly-skilled team across multiple areas of expertise will deliver a finished product that meets or exceeds your expectations.