What is CNC Laser Cutting?

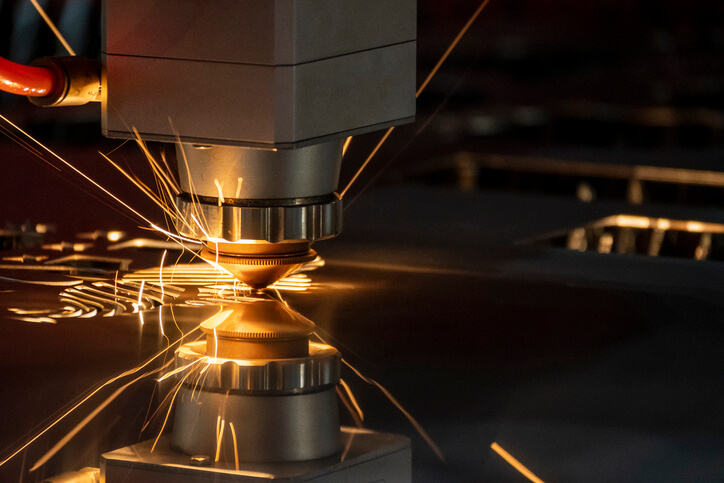

CNC (computer numerical control) laser cutting is a process wherein a high-powered laser beam cuts through materials like metal, plastic, wood, and more. As the name suggests, this process involves the use of computer numerical control to precisely cut the material according to a digital design file.

The process begins when an engineer creates a digital design file using computer aided design (CAD) software. Once that design is completed, the file is then loaded into the CNC machine’s computer, which controls the laser beam’s movement and intensity. With the help of a series of mirrors and lenses, the laser becomes a high-intensity beam that melts, vaporizes, or burns the material.

As the laser moves across the material’s surface, it follows the design file’s instructions and cuts out the desired shape with extreme precision. As this process is extremely efficient and versatile, it’s a common choice for various industries, including the manufacturing, automotive, and aerospace sectors, among others.

Advantages of CNC Laser Cutting

Now that we’ve established what CNC laser cutting is, let’s talk about how it can benefit your business.

Precision and Accuracy

One of the most significant advantages of CNC laser cutting is its precision and accuracy. As the laser beam is computer controlled, the cuts will be exact and uniform, every time. This level of precision is almost impossible to achieve with traditional cutting methods like sawing or milling.

Versatility

CNC laser cutting is extremely versatile, as it can cut through a wide range of materials, including metals, plastics, wood, and more. This makes it a great choice for a myriad of projects.

Speed and Efficiency

This manufacturing method is extremely fast and efficient, which reduces production time and increases productivity. Less labor hours per product means more money in your pocket.

Cost-Effective

Laser cutting reduces waste and eliminates the need for multiple cutting tools, which reduces the cost of tooling. Additionally, these machines require less maintenance than traditional cutting machines, which also reduces costs.

Clean and Safe

During the cutting process, the laser is contained within the machine, which eliminates the need for cutting fluids or other harmful substances. This makes it a safer option for workers, as there are fewer hazards involved in the process.

Environmentally Friendly

As aforementioned, CNC laser cutting produces less waste than traditional cutting methods as the laser beam produces a narrow kerf. Also, the machine consumes less energy than traditional cutting machines, which reduces the carbon footprint of the manufacturing process.

Disadvantages of CNC Laser Cutting

There are some disadvantages of pursuing laser cutting for your chosen manufacturing process.

You Need a Trained Operator to Run the Machine

A CNC laser machine is a complex piece of equipment that requires specialized knowledge and training to operate effectively and safely. If you chose to bring your cutting processes in-house, it may be difficult to staff an individual who can adequately run the machine.

Limited Material Thickness

Laser cutting machines are limited in the thickness of the metals they can cut. Usually, a machine can only cut up to 15 or 20mm; if your project calls for thicker materials, laser cutting won’t be your best option.

Weighing the Pros and Cons: Is it Right for You?

Overall, this manufacturing process offers more advantages than disadvantages. You’ll most likely want to outsource your cutting to a qualified third-party manufacturer, though, so you don’t have to spend a lot of money on the machines or operators.

Work with Cameron Manufacturing & Design for Your Laser Cutting Needs

Founded in 1983, Cameron Manufacturing & Design has decades of experience with laser cutting projects. We also specialize in a variety of metal fabrication projects, including machining, custom sheet metal fabrication, metal finishing, welding and fabrication, engineering design, and equipment installation services. Through organic growth, we are now a service provider to thousands of clients nationwide, and we’d be happy to help you with your next project.

We currently have two robust locations — one in New York and one in Florida — allowing us to serve a wide range of clients in those areas and beyond. At each of our locations, you’ll find a team of individuals dedicated to quality workmanship, on-time delivery, and a desire for unmatchable customer service. You’ll also find that we are ISO 9001 certified, which helps us create the best products for our clients.

Through these core beliefs and maintaining a positive outlook on the business, we’ve learned to adapt to a challenging and ever-changing industry, while withstanding the test of time.

Let’s Create a Partnership

Ready to explore what we can do for you? Reach out to our team for an initial consultation.

Recent Posts

- Crafting Excellence Bridging Heavy Fabrication and Light Manufacturing

- What is Precision Sheet Metal Fabrication

- Unveiling the Power of Custom Manufacturing Equipment in NY

- Cameron Manufacturing & Design: Your Top Choice for CNC Laser Projects

- The Power of Precision Machining in Custom Metal Fabrication

Trust the CMD Team With Your Next Project

Our highly-skilled team across multiple areas of expertise will deliver a finished product that meets or exceeds your expectations.