Custom Machining

Quality Workmanship Meets On-Time Delivery

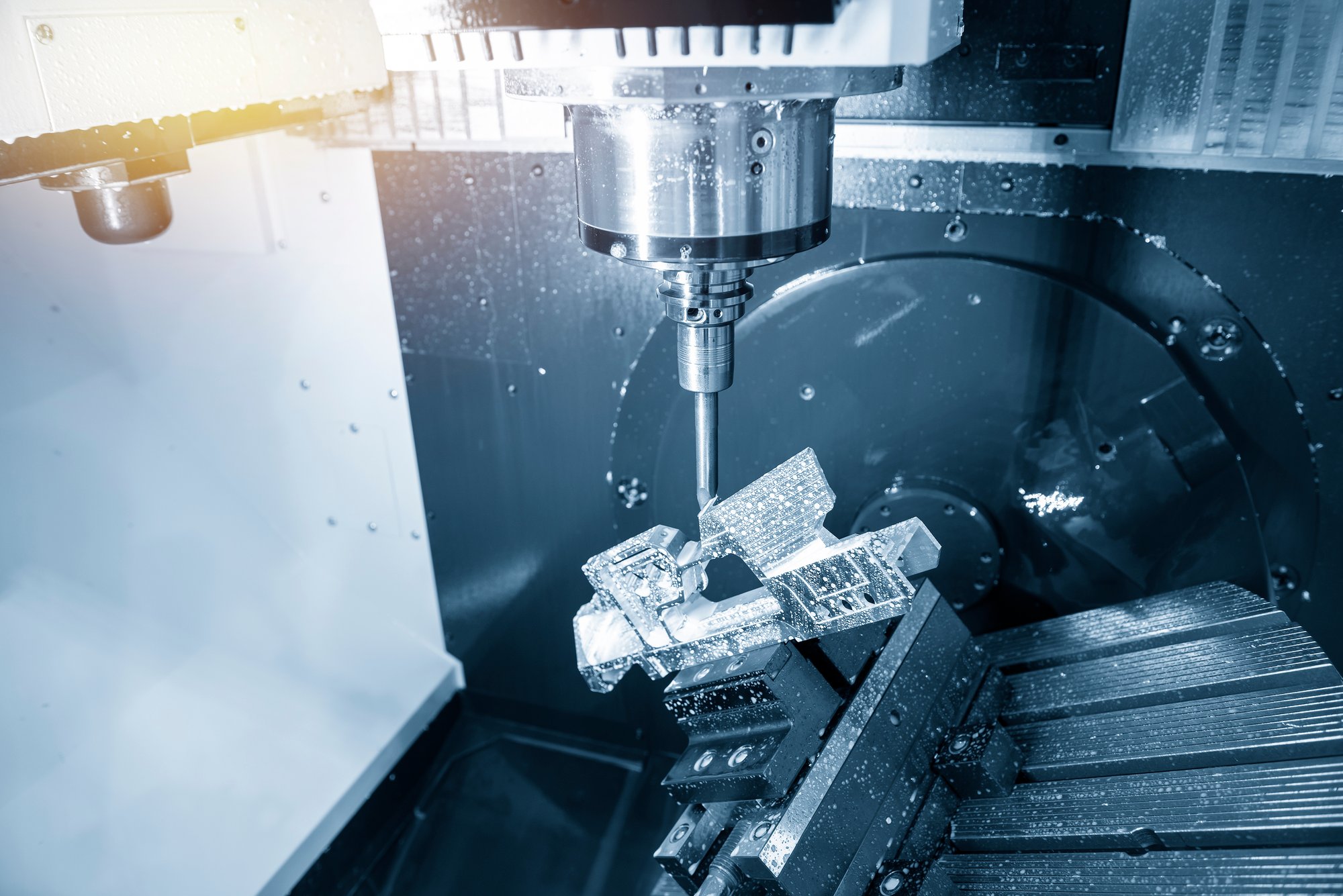

With two robust locations, hundreds of skilled employees, and industry experience dating back to 1983, Cameron Manufacturing & Design delivers excellent machined parts to clients across the nation. Our state-of-the-art machine shops include CNC programmed equipment that allows us to meet tight tolerances, adding precision custom machining capabilities to our turnkey operation.

How Our Custom Machining Excels

Our Machine Shop’s Advanced Equipment

Our state-of-the-art milling and turning equipment is at the forefront of precision fabrication. With advanced CNC technology and cutting-edge software, we ensure unparalleled accuracy and efficiency in our fabrication processes. From intricate designs to large-scale projects, our equipment is capable of handling a wide range of materials with precision and speed. With a commitment to innovation and quality, we continuously invest in the latest machinery to maintain our position as a leader in the industry

CNC Milling Equipment

- Hass VF-50 TR, full 5-axis contouring, 50-taper spindle w/2-speed gearbox

- Haas Super Mini-Mill 16” x 12” x 10”

- Haas VF-3 YT/50 (Vertical) 40” x 26” x 25”

- Two Haas VF-4 (Vertical) 50” x 20” x 25”

- Hass VF-4B, three axis, 8.1K RPM w/Shuttle Table

- Haas VF-5/40TR Trunnion Mill 38” x 26” x 25”

- Haas VF-6/50 (Vertical) 64” x 32” x 30” with fourth axis rotary

- Haas VF-7 (Vertical) 84” x 32” x 30” with fourth axis rotary

- (2) Haas VF-11 (Vertical) 120” x 40” x 30” with fourth axis rotary and full Renishaw inspection system on machine

- Haas VF-12 (Vertical) 150” x 32” x 30”

- Haas EC500 (Horizontal) 32” x 20” x 38” with full fourth axis rotary system – Pallet Changer

- Haas HS-7R (Horizontal) Machining Center 84” x 66” x 60” – 10,000 lb. table, four axis

- Forest Line Seramil VMC X-236” Y-94” Z-47” five axis programmable, 2.5 degree indexing

- Acer Knee Mill with X and Y NC Control

- Chevalier Knee Mill with X and Y NC Control

- Forest Liné Modumill VMC X-275″ Y-157″ Z-59″ five axis programmable, 2.5 degree indexing

CNC Turning Equipment

- Mazak QTN450MY 24” max diameter x 120” long, 8” Y-Axis 50HP, 10HP live tooling

- Haas SL-30 17” max diameter x 34” max length 30HP

- Hass ST-30 17” max diameter x 34” max length 30HP

- Haas SL-40 25.5” max diameter x 44” max length 15” chuck 40HP live tooling

- Hardinge Super Precision Quest 6/42 live tooling sub spindle

- Haas SL-20 10.5” max diameter X 20” max length

- South Bend manual lathe 12” x 50”

- Victor Lathe 16” x 60”

- Hardinge HLVH tool room lathe

Precision Laser Cutting and Water Jet Capabilities

At Cameron, our fiber laser and water jet equipment are the driving force behind our precision fabrication. With unmatched accuracy and efficiency, they bring our designs to life. Always pushing boundaries, we're committed to innovation to ensure top-notch results. With Cameron, you're not just getting a product; you're getting excellence powered by our cutting-edge equipment.

Laser and Waterjet Equipment

- Amada ENSIS 4020 AJ, 9,000 kw Fiber Laser, 72" x 144"— with Auto Sheet Loader

- Amada Punch/Laser — 2,500 watt LC 2012 CI NT with sheet loader

- Flow Mach 500 waterjet — 90,000 PSI

Ensuring Quality

CMD uses high-tech Creaform quality control equipment to scan our machined parts and verify quality. The trusted equipment we use in-house includes the MetraSCAN 750 Elite, HandyPROBE Next Elite, and MaxSHOT 3D. These then feed directly into our VXinspect and VXmodel software to quickly and accurately measure all scanned parts and pair with CAD software seamlessly.

Using this tooling and process, we’re able to perform geometric and freeform inspections on all of our custom machined, fabricated, and welded parts, from sizes of 12 inches or less to over 30 feet. This allows us to continuously verify the quality of our custom machining services and ensure that finished parts match design specifications exactly. Find out more about our commitment to quality and superior customer service here.

See Our Custom Machining At Work

Trust the CMD Team With Your Next Project

Our highly-skilled team across multiple areas of expertise will deliver a finished product that meets or exceeds your expectations.